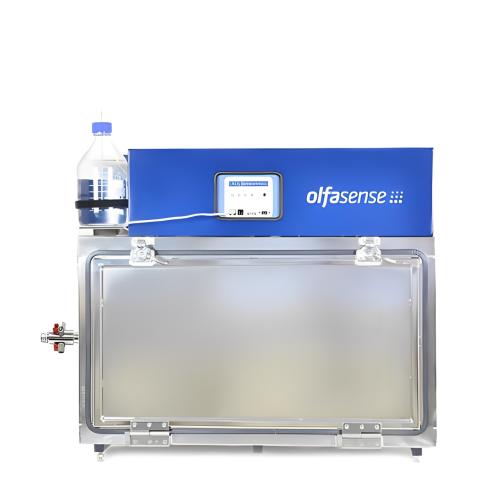

The EK250 emissions test chamber from Olfasense is designed for analysing volatile organic compounds (VOCs) emitted by building materials and consumer products. Compliant with ISO 16000-9, it provides a controlled environment for accurately measuring emissions under realistic conditions. With a volume of 250 litres, four sampling ports and an electronic air control system, the EK250 guarantees high parameter stability. Compact, reliable and efficient, it meets the needs of laboratories specialising in indoor air quality.

EK250 Emissions Test Chamber

Description

EK250 emissions test chamber: precise characterisation of VOCs according to ISO 16000-9

Indoor air quality is directly influenced by the presence of volatile organic compounds (VOCs) emitted by materials commonly used in the building industry, such as adhesives, paints, furniture and other furnishings. In order to assess these emissions, international standards recommend the use of specific test chambers. The EK250 chamber from Olfasense meets this need precisely, offering a rigorous testing solution that complies with ISO 16000-9.

With a capacity of 250 litres, this chamber simulates a closed environment in which the products being tested release their gaseous emissions. Its "emission-free" design limits the influence of the external environment on the results, ensuring reliable and reproducible analyses. Its electropolished stainless steel coating (DIN X 5 CrNi 18 10) prevents any interference with the compounds being analysed.

The EK250 can be integrated into a standard climate chamber (BINDER BF 720, optional), allowing tests to be carried out at temperatures up to 70°C. This flexibility is enhanced by a miniClima humidity control device and an adjustable ventilation system that guarantee stable conditions throughout the test. The use of a hot-wire anemometer enables precise measurement of the air velocity above the sample.

Designed for integration into laboratories specialising in VOC emissions, this chamber can also be continuously monitored via a data interface, with monitoring and evaluation options via a computer (optional). It is compatible with several chambers operating in parallel thanks to a serial/IP converter ( optional), which optimises analysis protocols in multi-sample test environments.

Compact (1000 x 600 x 800 mm) and weighing 60 kg, the EK250 combines robustness and efficiency. It is an essential tool for all professionals wishing to characterise material emissions according to strict and reliable criteria, in compliance with current international standards.

Features

- Compliant with ISO 16000-9

- Electropolished stainless steel chamber (DIN X 5 CrNi 18 10)

- Four sampling ports (1" with flexible connectors)

- Electronic flow and ventilation control

- Prevention of adsorption effects and external contamination

- Low noise level and energy consumption

- High-temperature testing possible via integrated incubator

- Data interface for continuous monitoring of parameters

- Device ready for use in a temperature-controlled room

Technical Details

- Chamber volume: 250 litres

- Dimensions (L x W x H): 1000 x 600 x 800 mm

- Weight: 60 kg

- Air flow rate: 1 to 10 l/min

- Air renewal rate: 0.24 to 2.4 h⁻¹

- Air speed above the sample: 0.1 to 0.6 m/s

- Operating temperature: +20°C to +70°C*

- Humidity range: 15 to 80% RH (between 5 and 35°C)

- Clean air supply: 15 l/min at 0.150 bar

- Power supply: 230 V, 50 Hz

- Power consumption: 120 W max

Compatible Accessories

- BINDER BF 720 incubator for extended temperature control

- Laptop with management interface

- Serial/IP converter for multi-chamber synchronisation

- 2L compensation bottle for humidity device

- miniClima system for precise humidity control