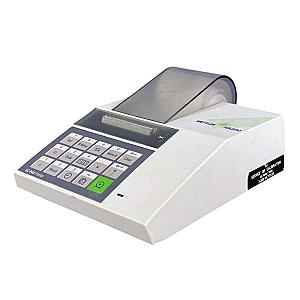

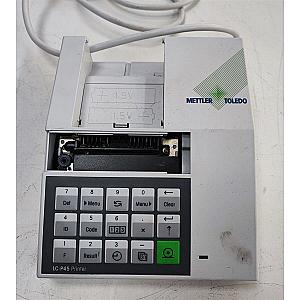

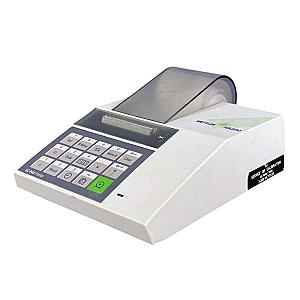

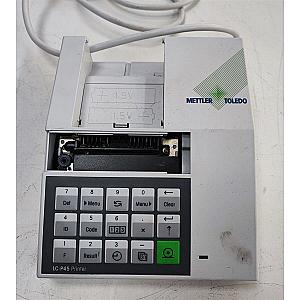

The LC-P45 from Mettler Toledo is a compact dot matrix printer designed for laboratory and industrial environments. It allows direct printing of weighing values, automatic addition of data such as date, time, sample identification and generation of statistics without external software. Compatible with Mettler Toledo balances and instruments via LocalCAN and RS-232-C interfaces, it ensures traceability in accordance with GLP and ISO standards. Robust, reliable and easy to configure, the LC-P45 is the ideal tool for documenting weighing, calibration and quality control operations.

LC-P45 Printer - Good Condition

Description

Mettler Toledo LC-P45 printer for weighing and calibration documentation

The Mettler Toledo LC-P45 is a dot matrix printer designed to meet traceability requirements in regulated environments such as pharmaceutical laboratories, quality control facilities and production units. With its ability to directly print weighing values along with critical data such as date, time, sample identification and batch number, the LC-P45 enables complete documentation in accordance with Good Laboratory Practice (GLP) and ISO 9001 standards. This printer connects easily to Mettler Toledo balances and instruments via its LocalCAN and RS-232-C interfaces, ensuring broad compatibility without complex configuration. It also supports Mettler Toledo's M-Pac application software, facilitating the recording of processes such as volumetric dosing, infrared drying or formulation.

Functional versatility for regulated environments

The LC-P45 does more than just print weighing values. It offers a comprehensive range of built-in functions that allow you to generate statistics on sample series, total weights for formulations, convert weights to volumes or prices, and document scale calibration and verification operations. These functions are accessible via an intuitive multilingual menu (French, English, German, Spanish, Italian) and settings are securely saved thanks to battery power. The printer can also be used for testing pipettes and other volumetric dosing devices, automatically calculating volumes from measured masses according to user-defined factors. Each operation is printed with the data required for regulatory compliance, ensuring seamless traceability.

Robust design and simplified maintenance

Designed for indoor use, the LC-P45 is splash and dust resistant, making it suitable for laboratory environments. Its durable housing allows for easy cleaning with common cleaning agents. The printer uses standard paper and easily replaceable ribbon cartridges. Thanks to its robust construction and low power consumption, the LC-P45 offers a long service life with minimal maintenance. It is also equipped with an automatic test to check the status of the print unit and identify any transmission or configuration errors. In the event of a malfunction, error messages are clear and allow for quick resolution, often without technical intervention.

Features

- Direct printing of weighing values

- Automatic addition of date, time, sample ID and batch number

- Generation of statistics without external software

- Weight totalisation for formulation

- Conversion of weights to volumes or prices

- Documentation of calibration and verification operations

- Pipette testing with automatic volume calculation

- Multilingual menu with parameter backup

- Compatibility with M-Pac software (CountPac, LabPac, etc.)

- Splash and dust protection

- Easy cleaning with standard agents

- Automatic testing of the printing unit

- Clear error messages for quick diagnosis

Technical Details

- Printer type: 5x9 dot matrix, 24 characters per line

- Print speed: Greater than one line per second

- Cartridge: Replaceable black ribbon

- Paper: Standard 58 mm x 51 mm roll

- Interfaces: LocalCAN and RS-232-C bidirectional

- Date format: EURO or US, leap years taken into account

- Buffer memory: 128 characters

- Power supply: 115 V or 230 V, 50/60 Hz

- Power consumption: 140 mA (115 V) or 70 mA (230 V)

- Dimensions: 157 x 210 x 85 mm

- Net weight: 1.5 kg (with paper roll)

- Operating temperature: 5 to 40 °C

- Relative humidity: Up to 80% at 31°C, decreasing to 50% at 40°C

- Installation category: II

- Pollution degree: 2

Compatible Accessories

- Paper rolls (set of 5) – Ref. 00072456

- Black ribbon cartridges (minimum pack of 2) – Ref. 00065975

- UM3/AA batteries (1.5 V) – Commercially available

- LocalCAN connection cable 1 m – Ref. LC-LC1, 00229154

- 2 m LocalCAN extension cable – Ref. LC-LC2, 00229115

- 5 m LocalCAN extension cable – Ref. LC-LC5, 00229116

- LocalCAN T-socket – Ref. LC-LCT, 00229118

- RS-232C cable 1 m – Ref. 11101051

- MiniMettler RS-232C cable 1.5 m – Ref. 00229029