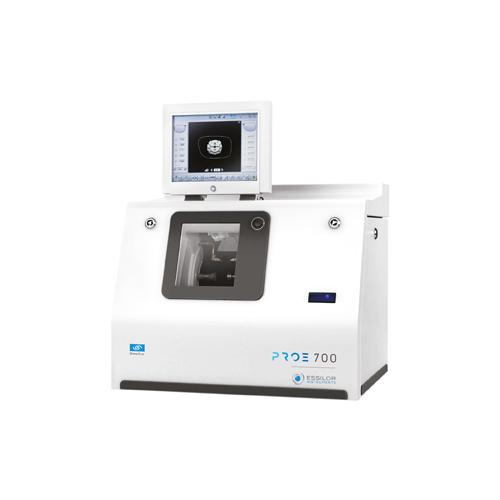

The PRO-E 700 is a high-precision edger designed by Essilor Instruments to meet the requirements of optical professionals. Featuring a 10-inch colour touch screen, it enables automated or customised machining of all types of finishes: bevel, chamfer, groove, drilling, polishing, engraving and creative shapes. Thanks to its modular tools and intelligent cycles, it guarantees optimal cutting quality on a wide range of materials, including high-index lenses and high-base sports lenses.

PRO-E 700 Edger - Perfect Condition 2021

Offer Details

Options :

Essilor PRO E 700 edger with Neksia tracer. Processes all organic lens materials. Standard features: milling, grinding, grooving, drilling (30°), mini bevel, sport bevel, step bevel, mixed bevel, polishing.

Description

The PRO-E 700: performance and versatility for the modern optician

The PRO-E 700 is a professional edger developed by Essilor Instruments, designed to offer maximum precision in the cutting and finishing of ophthalmic lenses. It incorporates technology that allows automated or fully customised machining, depending on the practitioner's needs. This model is particularly suitable for complex lenses, sports frames and creative work thanks to its many exclusive features.

State-of-the-art finishes and complete customisation

The PRO-E 700 supports a wide range of finishes: classic bevel, high base bevel, step bevel, flat edge finish, grooving, drilling, polishing, standard or "Super Chamfer" chamfering, and reworking. It also allows mixed jobs (e.g. bevel + groove) and complex drilling (holes, notches, oblongs). Each finish can be configured in automatic or custom mode, with precise adjustments to position, depth, width and angle depending on the type of material and the shape of the glass.

Custom mode offers total control over the trajectory of the chamfer or groove, with options for tracking the front face, rear face, curvature of the glass or edge of the frame. The user can modify the curve globally or point by point, or even move it without altering its shape.

Exclusive PRO-E 700 features: engraving and creative shapes

The PRO-E 700 includes features such as M'EYE Sign™ for custom engraving on lenses (excluding mineral glass) and M'EYE Touch™ for creating creative shapes. These features allow patterns, text or logos to be added to lenses, with precise positioning and sizing via Essibox or directly on the edger. The system can handle up to 500 jobs in series for engraving, with centring and blocking data saved.

The PRO-E 700 is also compatible with Chemistrie™ jobs, allowing additional magnetic clips (near vision, solar, blue light blocking, 3D) to be cut from the original ophthalmic lenses.

Features

- Automatic or customised machining

- Available finishes: bevel, high base bevel, staircase bevel, flat edge, groove, drilling, polishing, chamfering, retouching

- Custom engraving with M’EYE Sign™

- Shape creation with M’EYE Touch™

- Chemistrie™ work

- Mixed finishing methods (e.g. bevel + groove)

- Retouching after machining with preservation of parameters

- Tool wear indicators

- Integrated self-tests and diagnostics

- Touchscreen calibration

- Precision adjustment: diameter, chamfer/groove position, drilling diameter, engraving depth

- Saving of working habits

Technical Details

- Maximum lens diameter: 110 mm (90 mm with 10 mm off-centre)

- Minimum B dimension: 17 mm (flat edge), 18.5 mm (bevel)

- Colour touch screen: 10 inches

- Power supply: 220–240 V / 50–60 Hz or 100–120 V / 50–60 Hz

- Power consumption: 1350 W – 10 A (230 V) / 15 A (115 V)

- Dimensions: W 590 mm x D 490 mm x H 700 mm

- Weight: 95 kg

- Noise level: 71–72 dB depending on the material

- Operating temperature: +10 °C to +40 °C

- Humidity: 30% to 75%

- Maximum altitude: < 2000 m

- Network connection: RJ45 (viewing only on the edger)

Compatible Accessories

- Stylus for touch screens

- Posiblock removal pliers

- Triangular key

- White stone for finishing wheel

- Square stone for polishing wheel

- Transport wedges

- Accessory box containing:

- 22 mm and 18 x 14 mm posiblock holders

- Matching stops

- Lock key for tool change

- Drill bits Ø 1.0 mm and Ø 0.8 mm

- Milling cutters Ø 1.5 mm

- Grooving wheel Ø 20 mm

- Chamfer wheel

- Stepped bevel wheel

- Torque wrench

- High base chamfer wheel

- Metal ruler

- Modelling clay

- Adjustable wrench for tool change

- Spray kit (optional)

- Chip collection tray (optional)

- M'Eye Sign Box kit (optional)

- Essibox (optional)

- Connection cables: power supply, RJ45, Essibox

- Waste water drain hose with fixing ring