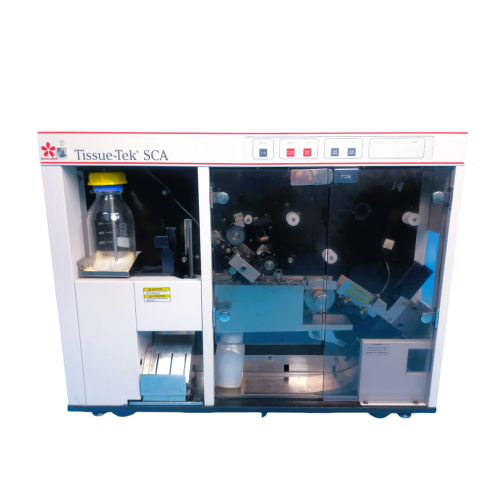

The Tissue-Tek SCA 4765 automatic lamination system from Sakura is a high-performance laboratory device designed to automate the lamination process for histological slides. It uses xylene-activated cellulose triacetate film, eliminating the need for glass coverslips and liquid mounting media. This device processes slides in three seconds with remarkable precision, ensuring considerable time savings, perfect process standardisation and immediate preparation for microscopic examination. Ideal for high-throughput laboratories demanding efficiency, quality and safety.

Tissue-Tek SCA 4765 Automated Lamination System - Fair Condition

Offer Details

Options :

As it is on the photos

Description

Tissue-Tek SCA 4765 Automated Lamination System – Performance and reliability for your histological preparations

The Tissue-Tek SCA 4765 from Sakura is a latest-generation lamination machine designed to optimise and automate the covering of slides in histological environments. Thanks to a xylene-activated triacetate cellulose film system, it replaces the manual lamination process with glass coverslips, saving considerable time and ensuring perfectly consistent results.

Each slide is inserted into the device via a loading basket, then automatically detected and processed. The system applies a precise volume of xylene, unrolls and cuts a strip of film, which is then placed on the slide with a pressure roller to ensure uniform adhesion. The entire process takes three seconds per slide. Once covered, the slide is transferred to a receiving basket, ready for immediate examination.

This system is managed by an intelligent microprocessor that controls the length of the film (45 mm or 55 mm), blade detection and xylene flow, and triggers safety alarms in the event of an anomaly: basket missing, door open, jam or film finished. This makes it a reliable and safe device, perfectly suited to environments with high workloads.

Its compact design (72 cm wide) allows it to be easily integrated into any laboratory, and daily maintenance is simple thanks to easy access to the xylene circuits, pressure rollers and cutting mechanism. Waste (film residue, used xylene) is collected in dedicated bins, and xylene vapour extraction can be connected to a fume hood or extraction system.

Robust, fast, accurate and easy to maintain, the Tissue-Tek SCA 4765 is the ideal ally for teams looking to modernise their lamination processes, reduce errors and guarantee high-quality sample visualisation under the microscope.

Features

- Complete automation of the lamination process

- Loading in trays of 20 slides, continuous processing

- Automatic blade detection and shutdown in case of anomaly

- Adjustable xylene application (6 to 10 drops/slide depending on application)

- Automatic film cutting (length of your choice: 45 or 55 mm)

- Application by uniform pressure for perfect adhesion

- Simple user interface with control panel and indicator lights

- Waste recovery system (xylene and film scraps)

- Ventilation outlet for connection to a hood or filtration system

- Safety sensors on doors, jam management and basket detection

Technical Details

- Power supply: 220 or 240 V ±10%, 50 Hz, 0.3 A

- Fuses: 2 A – 250 V time-delay, 5 × 20 mm (1 or 2 depending on voltage)

- Dimensions: width 72.1 cm × depth 27.4 cm × height 55.4 cm

- Weight: approx. 50 kg

- Operating temperature: 10 °C to 30 °C

- Relative humidity: 30% to 70%

- Processing speed: 1 blade every 3.6 seconds (at 50 Hz)

- Accepted blade size:

- Width: 24.6 to 26.2 mm

- Length: 74.7 to 76.5 mm

- Thickness: 0.9 to 1.2 mm

- Lamella film: Cellulose triacetate, 24 mm wide, 45 or 55 mm long

- Required solvent: Analytical grade reactive xylene (no substitutes or recycled xylene)

Compatible Accessories

- Tissue-Tek Lamination Film – Ref. 4770: triacetate cellulose rolls (5 rolls per box, >1000 blades/roll)

- Replacement cutting blades – Ref. 4772: 5 blades/box, to be changed every 10 rolls (~10,000 blades)

- Blade baskets – Ref. 4768: replacement baskets for 20 blades, 10 baskets per box